首页 >> Product >> Laser welding machine

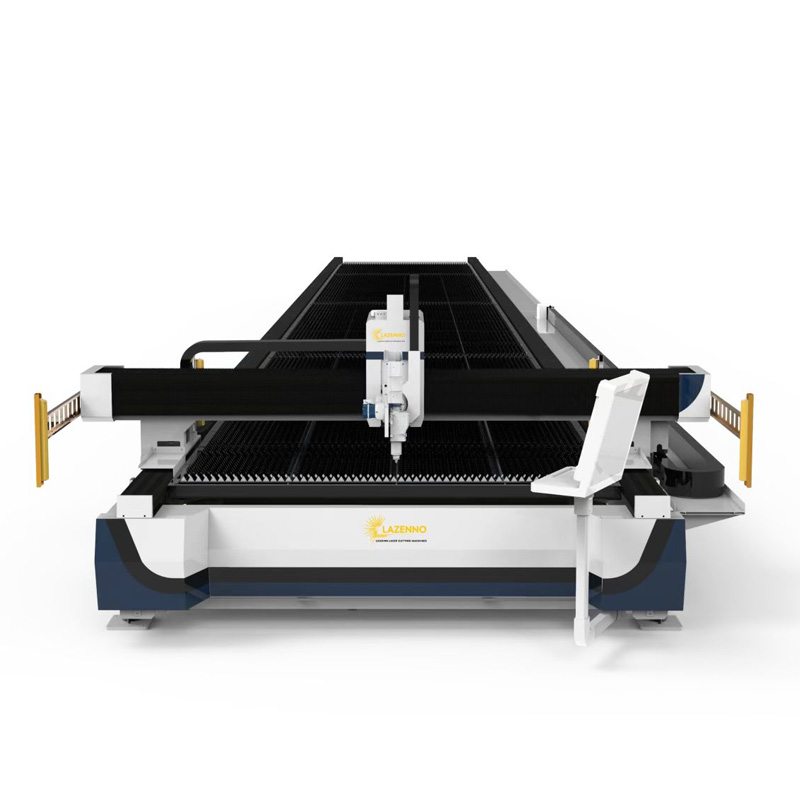

Laser cutting machines, with their core advantages such as high precision, high efficiency, non-contact processing and wide material adaptability , have become important equipment in modern manufacturing.

More +

Automobile manufacturing: The cutting accuracy of battery trays for new energy vehicles reaches 0.1mm

Aerospace: The thermal deformation of titanium alloy skin cutting is controlled within 0.02mm

In the electronics industry, the cutting error of OLED flexible screens is less than 10 microns

Youdaoplaceholder0 low cost of use :

The electro-optical conversion efficiency of the fiber laser cutting machine reaches 30%, and its power consumption is only 20-30% of that of the CO2 laser machine.

The comprehensive cost per hour is approximately 18 to 28 yuan, which is over 80% lower than that of traditional equipment.

Youdaoplaceholder0 easy to maintain :

There is no laser gas consumption, and the optical fiber transmission system eliminates the need for optical path calibration, reducing annual maintenance costs by 60%.

Youdaoplaceholder0 Core process advantages

Youdaoplaceholder0 High-precision cutting : The laser spot diameter can be focused to the micrometer level, achieving a dimensional accuracy of ± 0.05mm, and the cutting seam width is only 0.1-0.3mm, which is particularly suitable for the processing of precision parts.

Youdaoplaceholder0 excellent cutting efficiency :

The cutting speed is over 100 times that of wire cutting, and the cutting speed for 2-mm steel plates can reach 600 cm/min.

Operational flexibility

The handheld welding torch can achieve multi-angle and multi-directional welding, especially suitable for welding in narrow Spaces or complex workpieces, overcoming the limitations of the worktable of traditional welding equipment.

High-efficiency and precise welding

Laser welding is fast and has a small heat-affected effect. After medium and low power welding, no additional surface treatment is required. The strength of the weld seam can reach the standard of the base material, and the deformation is controlled within 0.5mm.

Low cost and high efficiency

The single-pass welding cost is 40% lower than that of traditional welding. The consumables only need to be regularly cleaned of the optical lens dust, and the accessories need to be replaced every half a year to one year.